| Section Page | Previous Page | Next Page |

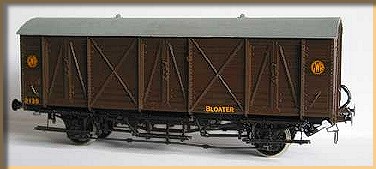

Parkside Dundas 4mm 'Bloater'by Graeme Pettit

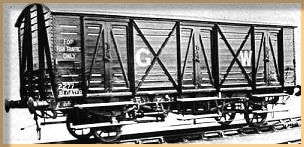

The GWR carried a heavy commitment to Fish Traffic from its numerous ports. The 'Bloater' Fish vans represented by the kit were originally built in 1916 to diagram S8. They were 28'6" long, with three sliding doors each side and vacuum fitted and gas lit. Ventilation of the vans was originally by louvres in the body (photo above). Later, roof ventilators were fitted. Whilst the vans were designated as freight vehicles, they could often be found, as with milk tankers etc, stuck on the back of passenger services. Visually, they were similar to the Fruit 'D' vans, the major difference being in the doors The vans were created in order to scrap a very aged fleet of miscellaneous vans built between 1880 and 1918, and used at the time for fish traffic. The Bloaters were removed from revenue earning service around 1943, but were placed in departmental use, and remained so, well into BR days. The number series of the S8 vans was between 2139 and 2213. For further reference, see: "History of GWR goods Wagons" by Atkinson, Beard, Hyde and Tourret (Publisher: David and Charles).

Overall, the instruction sheet is very good, and easy to follow. I found that the 'plastic weld', or MekPak watery type glue was easiest to use, and is my standard other than Superglue. As can be seen from the picture of the model, perhaps the biggest problem with this kit is how to keep the truss rods straight ! These have been modelled with very fine plastic, which appears to expand with heat, eventually forcing themselves so far out of alignment that the effect above is plainly visible. This has happened to both kits of this type I have built so far. I would recommend replacing them with fine grade straight brass wire. This is what I will do when I get around to it. Otherwise, the kit is nicely moulded, and went together exceptionally easily and without fuss. Parkside have also made some other parts, such as the brake lever and step mountings, particularly lightweight in order to improve the overall appearance of these kit. Whilst the mouldings are relatively flash free, there are many very small parts that are both brittle and easily lost, which makes them difficult to locate for people with big fingers and little patience. The builder may wish to replace these with slightly heavier whitemetal castings. Personally I like them as they are, and try not to abuse my models with rough handling. It pays to drill all brake shoes, vee hangers etc, and link with wire to add strength to the final assembly, and to form the brake linkages for added strength in the underframe department. The turned buffers, whilst solid, are wrong for the type, and would be better replaced by suitable cast items. Other than the above, construction is straightforward, and the only additional items you will need are your choice of couplings, and vacuum pipes. |

| Section Page | Previous Page | Next Page |