Although RTR models are getting better and better, there is still room for improvement, especially beneath the footplate. On this page, Norm Hodges illustrates how he enhances the running and detail of his RTR locos.

IntroductionI'm in the process of upgrading some RTR locos and also building kits to achieve the models I want. If I can find a proprietary model that can be altered or adapted to give a reasonable representation of what I want, then that's the way I go. I'm getting too old and too short on cash to be true to scale accuracy these days, and the hobby should be enjoyable anyway. |

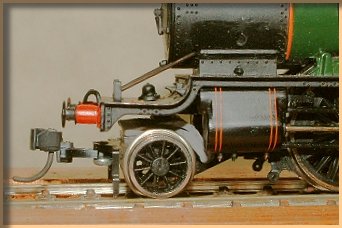

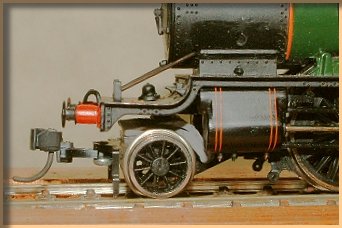

Bachmann 43xx with lead weight and Kaydee coupling

|

Adding lead to pony trucksSome offerings from the RTR manufacturers have problems with the pony trucks in terms of weight, balance and sideplay – leading to derailments on points and curves. Here the problem is solved on a Bachmann 43xx by shaping some folded lead sheet and gluing it to the top of the pony truck. It is important to leave enough clearance for the truck to rise slightly with any changes in track levels. |

Close up of modified 43xx pony truck showing lead weight

|

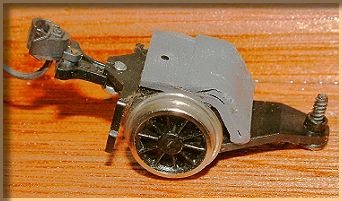

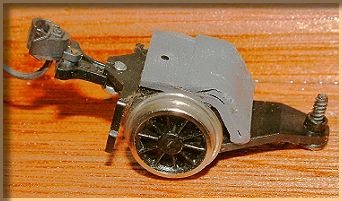

Replacing pony trucksAnother option is to fit new pony trucks altogether. This photo shows a couple of pony trucks built from Comet Models etched brass kits, and they behave faultlessly. They were made for a kit-built 72xx loco, the left being the trailing one and the right being the leading one. The trucks were made in different lengths to suit, and should also be suitable for fitting to RTR locos.

|

Two Comet pony trucks

|

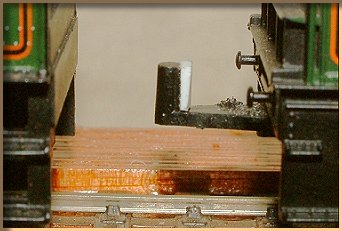

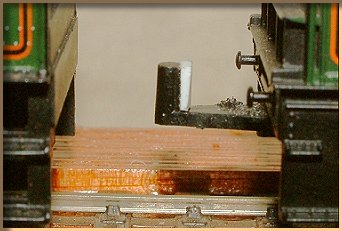

Replacing the chassisThe ultimate modification to the chassis is of course to replace it altogether. Comet have a range of etched brass kits available to build replacement chassis for both kits and RTR models. This photo shows an example of a Comet chassis fitted to a Bachmann 56xx class loco, using Ultrascale wheels. |

Comet chassis with Ultrascale wheels

|

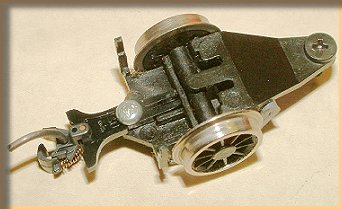

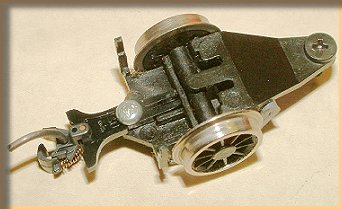

Fitting Kadee couplingsThe American-made Kadee couplings are increasingly being used by British modellers for improved scope and operation in coupling. This photo is a close up of a Bachmann 43xx pony truck upside down to show where the NEM No. 20 Kadee was drilled and fixed. |

Comet chassis with Ultrascale wheels

|

Closing the gapLike some other RTR locos, the 43xx has a rather large gap between tender and loco, designed to allow for tight curves. The photo shows how plastic can be glued to the tender drawbar to close the gap. Fall plate and crew still to be fitted in this picture. |

Tender drawbar, modified to narrow the gap |